How to Evaluate Quality of Ceramic Tiles & Vitrified Tiles

First know the difference

- While both fall under class of ceramic tiles, the difference is not only in manufacturing process but also properties.

- Ceramic tiles are made of baked clay while Vitrified tiles are made of clay and silica (approx. 60% & 40%) fired at higher temperature ( 1000 C plus).

- So vitrified tiles are stronger, denser and have lower water absorption when compared with Ceramic Tiles.

- Both should be suitably used base on application.

What are different types of Ceramic Tiles ?

Tiles which have glassy top surface are called glazed tiles or they could be unglazed. If the tiles are having sharp straight edges which have been cut in manufacturing they are called rectified while ones whose edges are not worked are called unrectified. Vitrified tiles which have uniform composition through out its body are full body vitrified tiles. Double Charged vitrified tiles are fired twice with a bottom layer of vitrified section and a top layer vitrified section with pigments for aesthetics. Double Charged vitrified tiles do not have a glaze and are non slippery.

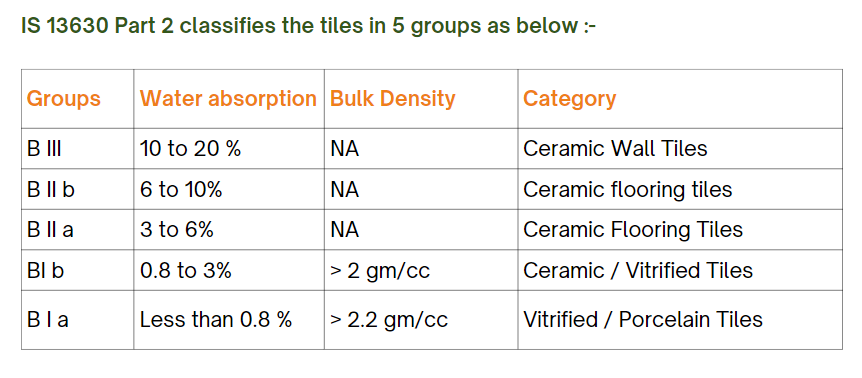

What is the classification of Tiles based on quality ?

Where to use different ceramic tile groups.

How is quality of ceramic tiles is evaluated ?

- Various tests are recommended in IS 13630 – 2006 on ceramic tiles which include

- Water Absorption / Bulk Density for tile classification

- Dimensional Analysis and Surface Quality tests for better aesthetics

- Breaking load / Modulus of Rupture / Abrasion test for wear and tear

- Crazing Resistance / Chemical resistance / Linear Thermal Expansion for long term performance.

How do you ensure that you get right material ?

- The quality requirements of each of above groups are different.

- It is important to specify the group correctly while placing your order

- Regular testing of each consignment will minimize the flooring defects.